WENCON Products

To view your Pricing or to make purchases, please create an account, easily done here. New customers signing up for account with CorrosionXpert, will automatically benefit from our advance discount program. Already a customer, please sign in to your account to view pricing or to make purchases.

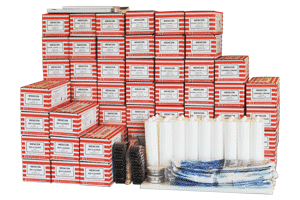

Standard Products

Under Water Products

High Performance

Repair Kits

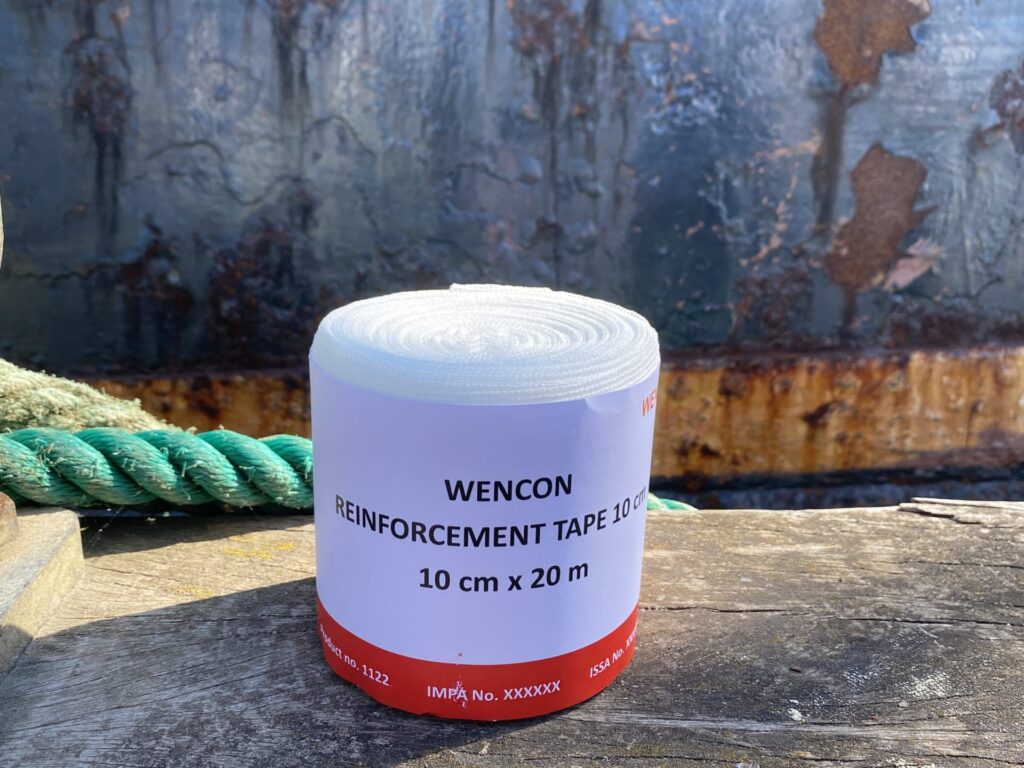

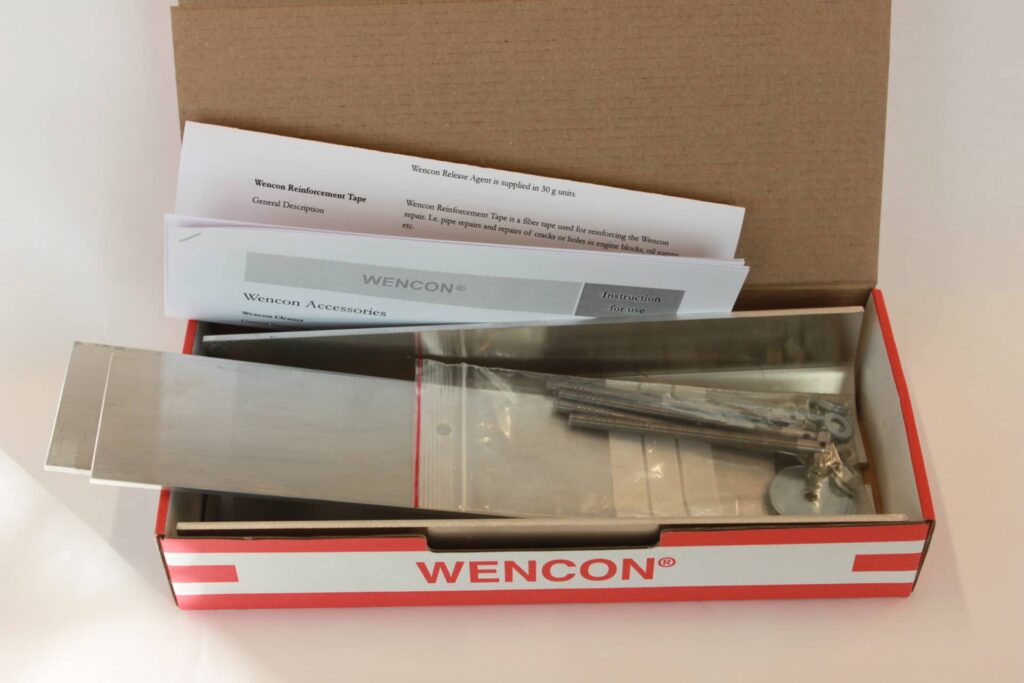

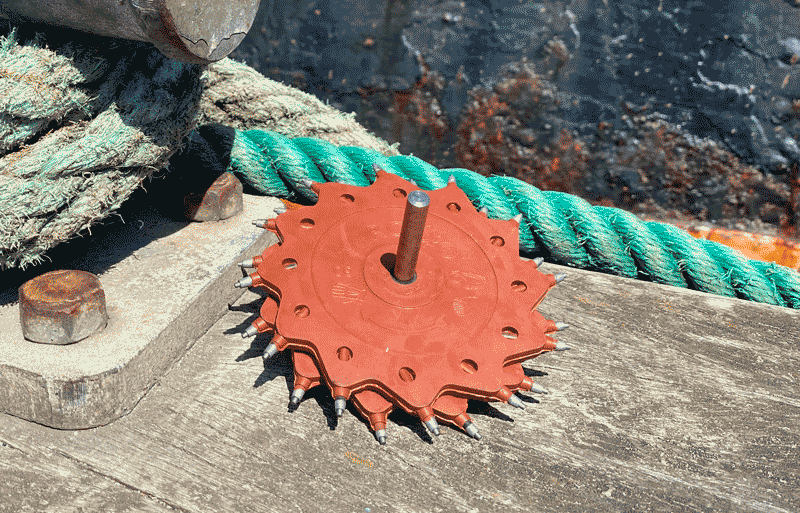

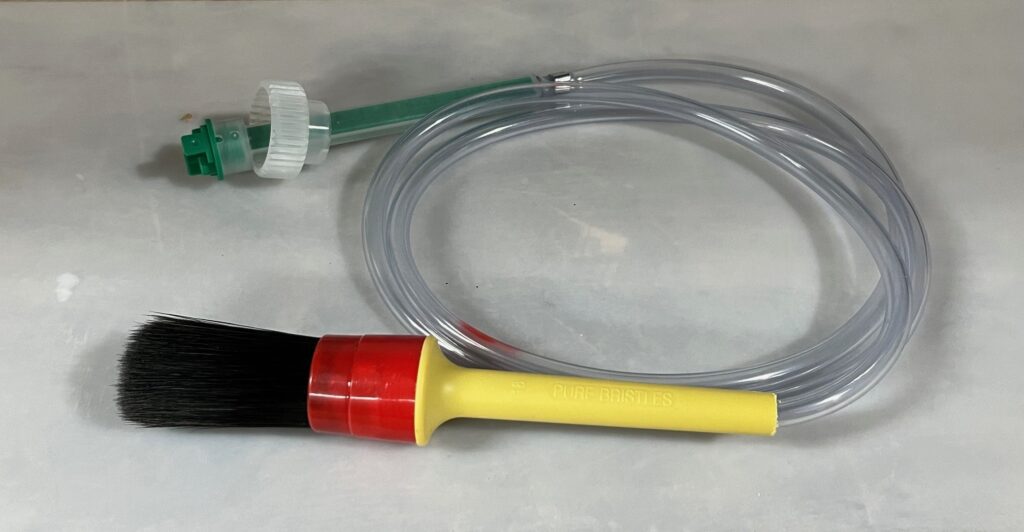

Accessories

How do Wencon products contribute to environmental sustainability?

- Low Environmental Impact Materials: Wencon often utilizes materials with a low environmental impact in the production of its products. This includes formulations that are non-hazardous and have minimal impact on ecosystems.

- Extended Asset Lifespan: By effectively repairing and protecting equipment, infrastructure, and assets, Wencon products help extend their lifespan. This reduces the need for frequent replacements, thereby minimizing the overall environmental impact associated with manufacturing new components.

- Corrosion Prevention: Wencon products are designed to protect metal surfaces from corrosion. Corrosion can lead to premature failure of equipment, and by preventing it, Wencon contributes to the reduction of material waste and the environmental footprint associated with replacement.

- Reduced Energy Consumption: Extending the life of machinery and infrastructure through effective maintenance and repair with Wencon products can lead to reduced energy consumption. Equipment in good condition tends to operate more efficiently, consuming less energy and contributing to energy conservation.

- Innovative Solutions: Wencon invests in research and development to create innovative and environmentally friendly solutions. This may include the development of products with reduced environmental impact or the introduction of technologies that enhance sustainability in the repair and maintenance processes.

- Reduction in Hazardous Waste: Wencon’s focus on providing durable and long-lasting solutions helps reduce the generation of hazardous waste associated with frequent replacements. This is particularly relevant in industries where hazardous materials are commonly used.

- User and Environmental Safety: Wencon products are often formulated with user and environmental safety in mind. This includes minimizing the use of harmful chemicals and ensuring that products can be applied safely, reducing the risk of environmental contamination during application.

By incorporating these practices and features, Wencon products contribute to environmental sustainability by reducing waste, conserving resources, and promoting responsible maintenance and repair practices across various industries.

What certifications and quality standards do Wencon products adhere to?

Wencon ApS is certified acc. To 9001 standards. And Wencon products are type approved by all major Class societies, including:

- Lloyds Register

- DNV/Lloyds

- ABS

- Bureau Veritas

- Rina

Which specific Wencon products are recommended for different types of repairs and maintenance tasks?

Wencon offers a range of products designed for various types of repairs and maintenance tasks across different industries. The specific product recommendations may vary based on the nature of the repair or maintenance needed. Here are some examples:

Wencon Coating:

- Application: Protective coating for corrosion prevention on metal surfaces. High impact, Abrasion, heat and chemical resistance, Strong adhesion to all steel and metal surfaces, Single and double coat system, High coverage rate, Non-electrical leading, 100% solid, no shrinkage

- Recommended for: Marine structures, offshore equipment, pipelines, tanks, and industrial machinery.

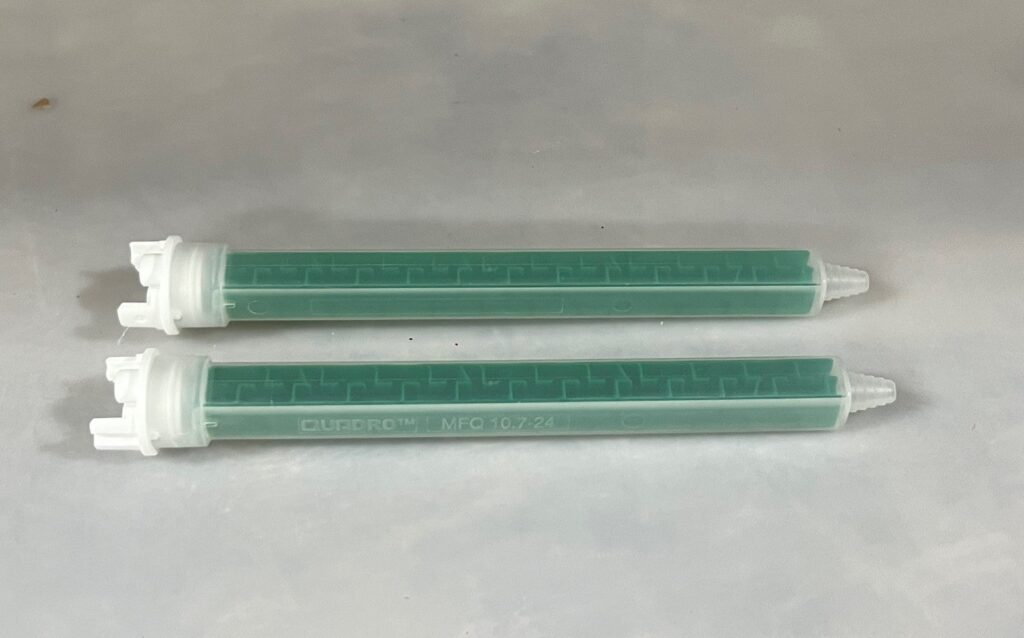

Wencon Repair Filler (Wencon cream and Wencon Rapid):

- Application: Filling and rebuilding damaged surfaces. And fast-setting adhesive for bonding various materials. High impact, Abrasion, heat and chemical resistance, Strong adhesion to all steel and metal surfaces, High coverage rate, Non-electrical leading, 100% solid, no shrinkage

- Recommended for: Repairing pitted or worn surfaces on metal components in marine, offshore, industrial, and infrastructure applications.

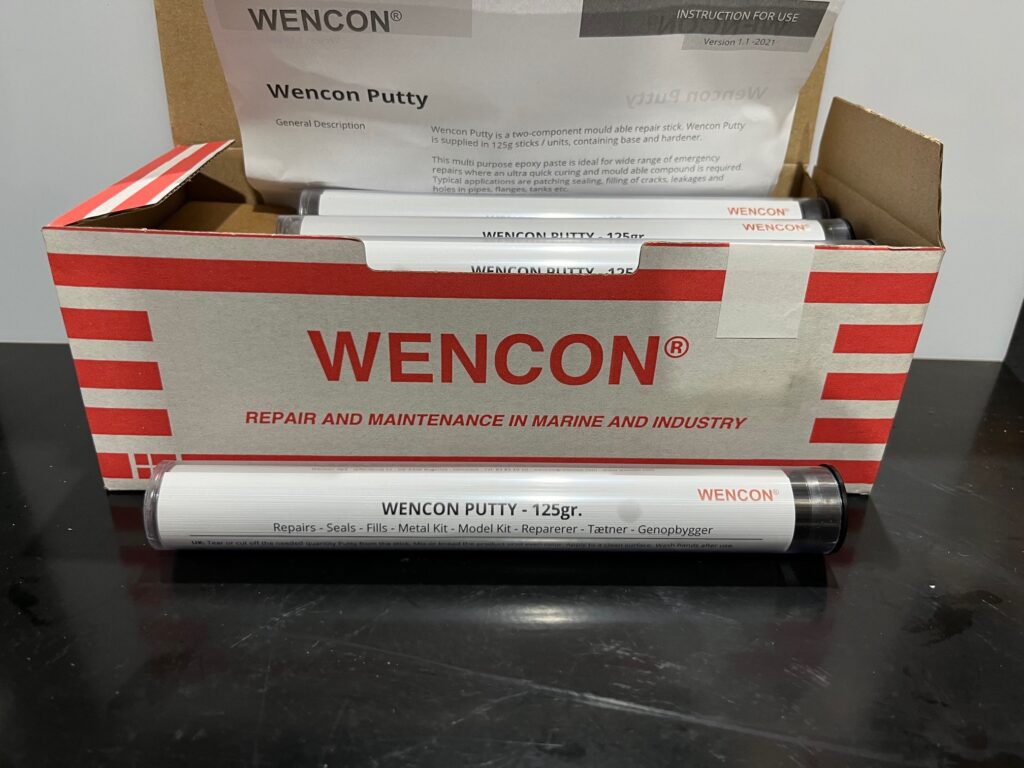

Wencon Rapid Steel Putty:

- Application: Quick-setting steel putty for instant repairs. High impact, Abrasion, heat and chemical resistance, Strong adhesion to all steel and metal surfaces, High coverage rate, Non-electrical leading, 100% solid, no shrinkage

- Recommended for: Rapid repairs on various metal surfaces in industries such as manufacturing and construction.

Wencon UW (Under Water) Repair Putty:

- Application: Underwater repairs and maintenance, above water repairs and maintenance. High impact, Abrasion, heat and chemical resistance, Strong adhesion to all steel and metal surfaces, High coverage rate, Non-electrical leading, 100% solid, no shrinkage

- Recommended for: Emergency repairs on ships, offshore structures, and other submerged & non-submerged equipment.

Wencon UW (Under Water) Coating:

- Application: Environmentally safe coating for protection against corrosion, underwater and above water. High impact, Abrasion, heat and chemical resistance, Strong adhesion to all steel and metal surfaces, Single and double coat system, High coverage rate, Non-electrical leading, 100% solid, no shrinkage

- Recommended for: Industries with strict environmental regulations, such as offshore and marine.

Wencon UW Cream/filler:

- Application: Fast-setting adhesive for bonding various materials. And for restoring corroded, eroded or worn out surfaces, underwater and above water. High impact, Abrasion, heat and chemical resistance, Strong adhesion to all steel and metal surfaces, High coverage rate, Non-electrical leading, 100% solid, no shrinkage

- Recommended for: Quick bonding applications of dissimilar materials, eliminating bi-metallic corrosion

Wencon Ceramic cream/filler:

- Application: High-temperature resistant repair compound. High impact, Abrasion, heat and chemical resistance, Strong adhesion to all steel and metal surfaces, High coverage rate, Non-electrical leading, 100% solid, no shrinkage

- Recommended for: Repairing and protecting equipment exposed to high tear and wear, such as found in the Marine, offshore, chemical and petrochemical industries.

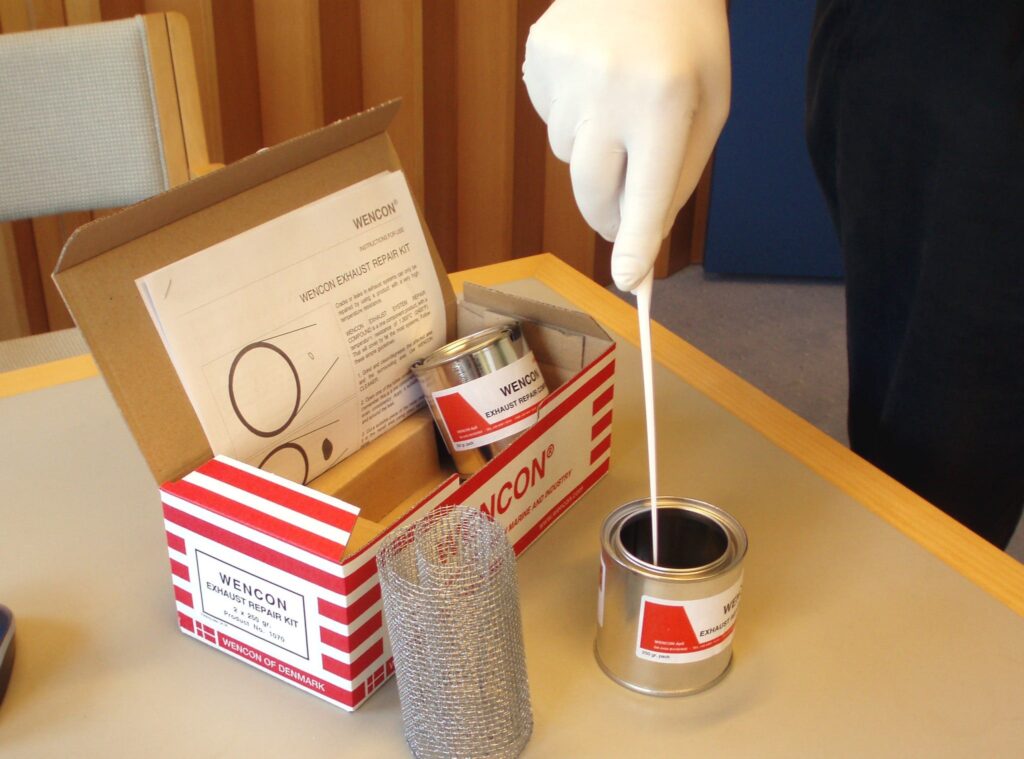

Wencon Exhaust Repair (One-Component Cold Weld paste):

- Application: Cold-welding compound for bonding and repairing Exhaust systems.

- Recommended for: Repairing metal components in situations where traditional welding is impractical.

Wencon Hi-Temp Coating:

- Application: Heat-resistant coating for protection in high-temperature surfaces and high-temperature environments. High impact, Abrasion, heat and chemical resistance, Strong adhesion to all steel and metal surfaces, Single and double coat system, High coverage rate, Non-electrical leading, 100% solid, no shrinkage

- Recommended for: equipment exposed to high temperatures, such as heating and steam piping systems and hot covers, etc..

Wencon Coating CS High Build:

- Application: Extreme high build coating with High impact, Abrasion, heat and chemical resistance, Strong adhesion to all steel and metal surfaces, Single and double coat system, High coverage rate, Non-electrical leading, 100% solid, no shrinkage

- Recommended for: Rudder and hull, Steel and concrete storage, tanks, Separators, Evaporators, Scrubbers, Absorbers, Heat exchangers, Turbines, Pipelines and pumps and Vessel propulsion areas.